PMB Moisture Analyzer

Applications

Features

Overview

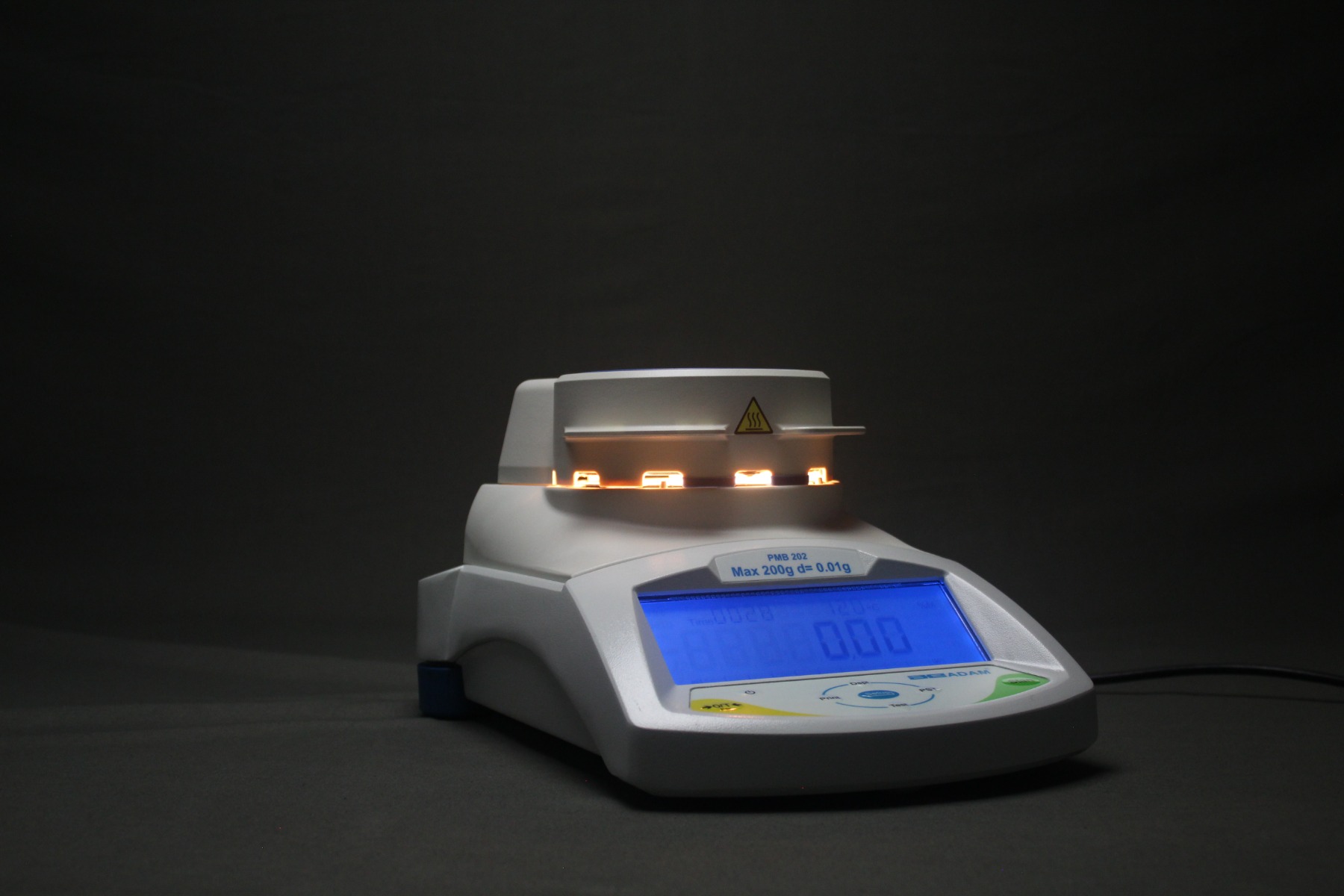

Adam PMB Moisture Analysers provide excellent value with high-level features. No additional software is required to run tests and take readings. PMB offers the freedom to collect data in the lab or in the field. The included halogen bulb heats samples evenly and consistently with 1°C selectable increments.

What is the PMB Moisture Analyser used for?

Moisture analysers are used to determine moisture content in food, oils, creams, and building materials like cement. They're also ideal for cosmetics, food testing, quality control, agriculture and laboratories.

PMB Quick Start Guide

How to Use the PMB Moisture Analyser

With simple operation and rapid response time, PMB moisture analyzers offer the top value in their class.

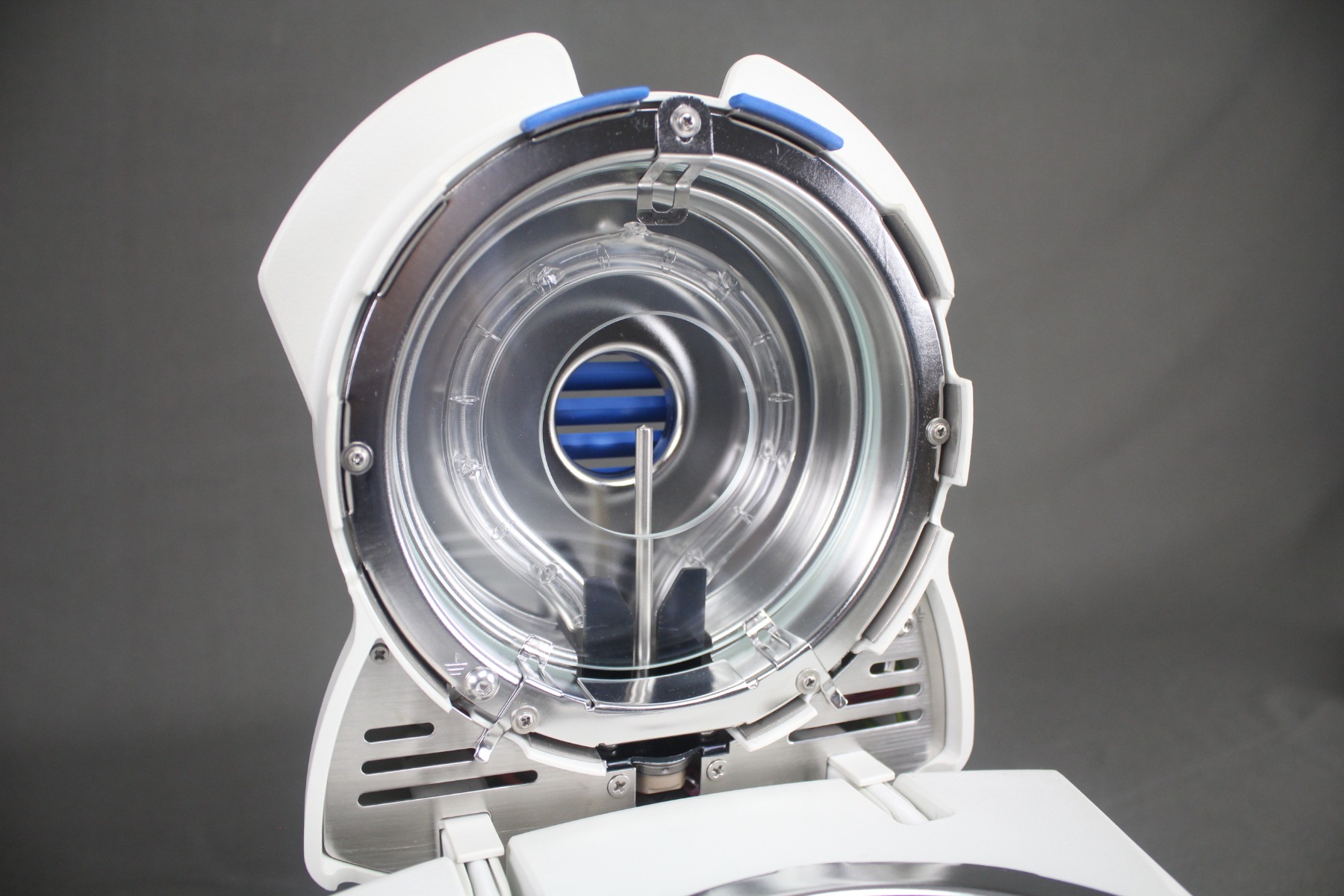

A single 400-watt halogen bulb heats samples in 1 °C selectable increments. Three heating options give users the flexibility to customize test methods and temperatures for different materials.

The automatic test-setting function enables easy recall for frequent testing of the same items without additional user programming. USB and RS-232 interfaces provide computer and printer connections to store test programs and results. No additional software is needed to take readings, giving users total freedom to collect data on a production floor or in the field.

The PMB can be used to accurately determine the moisture content in food samples, oils and creams. Suitable for cosmetics, agriculture, food testing and science laboratories.

For more information on the PMB moisture analyzer, please contact us.

Features and Benefits

- Vivid, backlit LCD easily visible in any lighting conditions

- Programmable backlight can be set to "always on," "always off" or "light only when weighing"

- Capacity tracker built into display for easily monitoring possible overloads

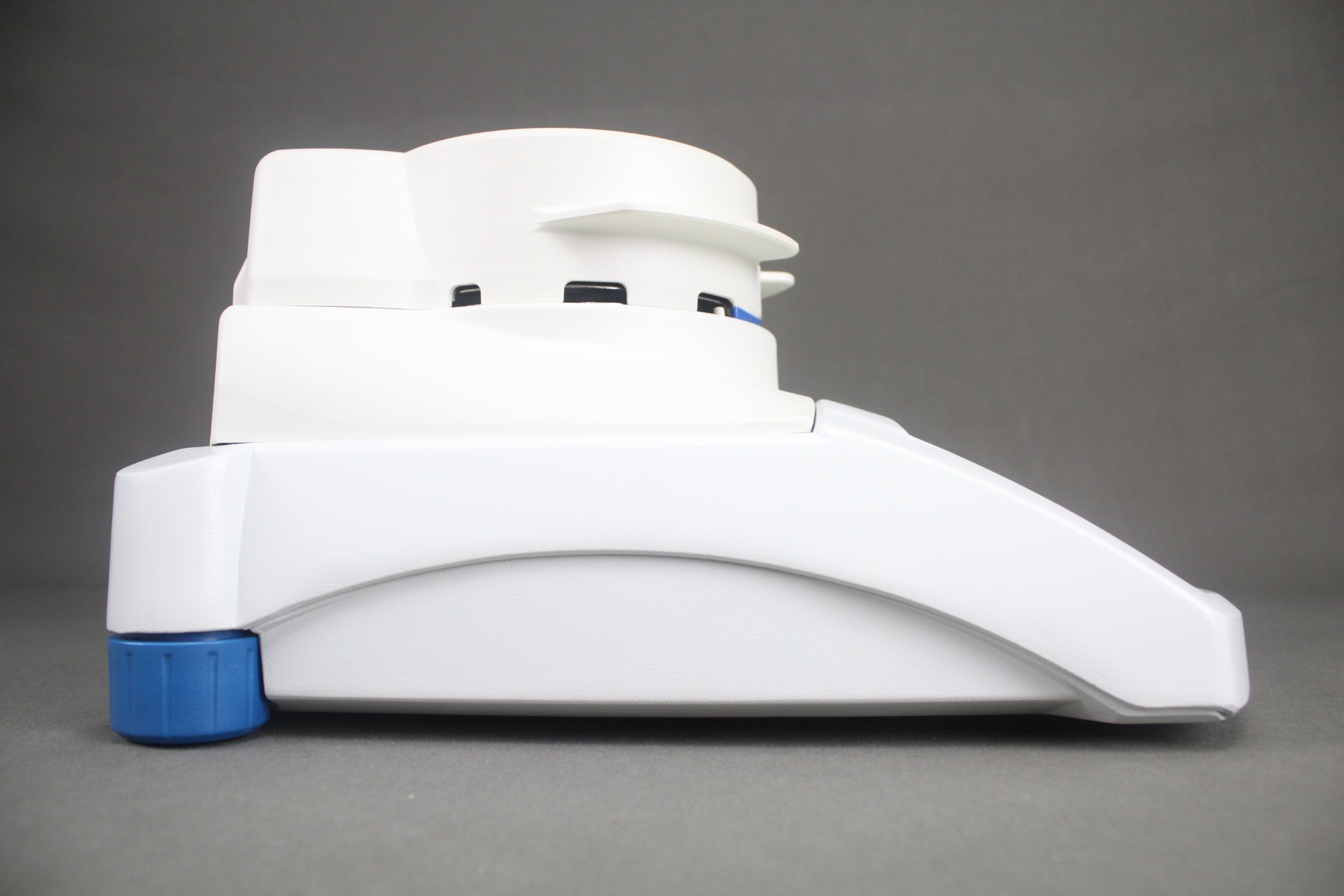

- Scratch-resistant aluminum housing protects internal components

- Color-coded keys facilitate quick recognition of the most frequently used buttons

- Pan lifter allows easy placement and removal of samples

- RS-232 interface provides speedy connection to computers and printers

- USB host for memory card and USB I/O interface

- USB interface included for data communication

- Temperature range 50°C to 160°C in one-degree increments

- Power cord

- Three settings for heating sample include ramp-up, stepped temperatures and single temperature

- Four preset drying modes allow test routines for several products

- Audible overload alarm warns when capacity is exceeded

- Testing can be set to start automatically when lid closes

- Calibration for temperature and weight

- Multilingual display permits use in various regions

- Quick and easy configuration using the keypad

- Zero-tracking feature ensures display returns to zero reading

- Internal memory stores 49 different recipes and up to 99 test results, while additional test results and settings can be stored on a flash drive

- Security slot for optional lock and cable to help prevent theft

- A 5-year warranty means quality assured for years of use.

Models

PMB 53-115V PMB 53-115V | 50g | 0.001g / 0.01% | 3.9" / 100mm ø | ||

PMB 53 PMB 53 | 50g | 0.001g / 0.01% | 3.9" / 100mm ø | ||

PMB 163-115V PMB 163-115V | 160g | 0.001g / 0.01% | 3.9" / 100mm ø | ||

PMB 163 PMB 163 | 160g | 0.001g / 0.01% | 3.9" / 100mm ø | ||

PMB 202 PMB 202 | 200g | 0.01g / 0.05% | 3.9" / 100mm ø | ||

PMB 202-115V PMB 202-115V | 200g | 0.01g / 0.05% | 3.9" / 100mm ø |